In the crowded world of marketing, getting your brand to stick quite literally can be a challenge. We have worked with countless business owners who spend a fortune on digital ads that disappear with a scroll, yet they overlook one of the most tangible, lasting marketing tools available. There is something uniquely powerful about handing a customer a physical token of your brand that they actually want to put on their laptop, water bottle, or car bumper.

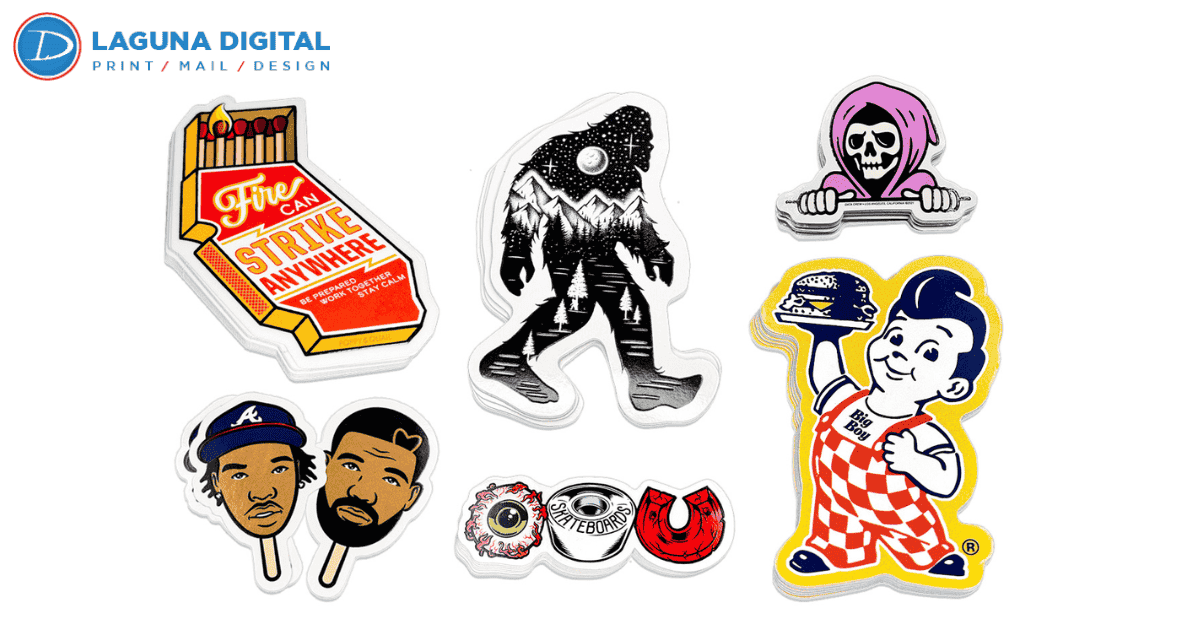

This is where the magic of custom shaping comes in. Specifically, we are talking about Die Cut Stickers. If you have ever seen a sticker that looks like it was laser-focused on the image itself, with no extra white background or generic square border, you have seen a die cut sticker. Unlike standard options, these stickers are cut specifically to the shape of your design, creating a premium look that immediately signals professionalism and creativity.

However, understanding exactly what they are and how to design them correctly can be tricky if you haven’t spent years in the printing industry. From file preparation to choosing the right finish, the details matter. In this guide, we are going to break down everything you need to know from a production perspective, helping you avoid common pitfalls and ensuring your brand makes the impact it deserves.

Understanding the Die Cut Difference

To understand why these stickers are special, we have to look at how they are made. The term die cut originates from the manufacturing process where a die essentially a sharp, custom-shaped metal cutter similar to a cookie cutter is used to punch out the material. In modern digital printing, we often use precision plotters, but the principle remains the same: we are cutting through both the sticker material and the paper backing.

This distinction is crucial because it affects the customer’s first impression. When you hand out a die cut sticker, the recipient is holding an object shaped exactly like your logo or mascot. There is no excess backing paper framing the design. This creates a psychological effect where the item feels like a piece of merchandise rather than just a sticky label. It implies that you cared enough about your brand to invest in a custom form factor rather than settling for a standard template.

Many of our clients confuse these with kiss cut stickers. The difference is subtle but important. Kiss cuts only slice through the vinyl layer, leaving the backing paper intact as a square or rectangle. While kiss cuts are easier to peel, they don’t have the same wow factor as a die cut sticker when handed out individually at events or included in packaging.

Why Custom Shapes Elevate Branding

We often ask our clients: Does your brand fit in a box? Usually, the answer is no. So why should your stickers? The primary advantage of die cutting is visual impact. Our eyes are naturally drawn to unique contours and silhouettes. A sticker shaped like a coffee cup, a surfboard, or a complex typographic logo stands out significantly more than that same design printed inside a white circle.

By utilizing branding with unique shapes, you are essentially turning your logo into a standalone piece of art. This encourages people to actually use the sticker. We have seen time and again that customers are far more likely to place a cool, custom-shaped decal on their expensive electronics or gear than a generic rectangular bumper sticker. It moves the item from advertisement to accessory.

Furthermore, custom shapes allow for versatility in placement. Without the constraints of corners or excess background, these stickers can fit into odd spaces on equipment, packaging, or signage. This flexibility is vital for businesses that want their branding to look native to the surface it is applied to, rather than looking like a slapped-on afterthought.

When Standard Shapes Are Still the Best Choice

While we love the creativity involved in custom die cutting, we always believe in using the right tool for the job. There are plenty of scenarios where standard geometric shapes are actually the superior choice, particularly when it comes to product labeling or uniform packaging. It is important not to overcomplicate things just for the sake of it.

Geometric Consistency

If you are labeling jars, boxes, or bottles, you often need a consistent surface area to display ingredients or barcodes. In these cases, oval stickers can provide a classic, elegant look often used in the cosmetic and food industries. Similarly, round stickers are perfect for sealing tissue paper in e-commerce deliveries or adding a Thank You seal to an envelope.

Information Density

Sometimes, you just need real estate for text. If you have a lot of information to convey, such as operating instructions or a detailed event lineup, square stickers or rectangle stickers maximize the printable area. They offer a clean, organized look that helps maintain readability, which is critical for functional labels rather than purely aesthetic ones.

Specialized Applications

We also see specific use cases where the shape is dictated by the container. A prime example is hand sanitizer stickers. These usually require specific dimensions to fit the small travel-size bottles widely used for promotional giveaways. In this context, a custom die cut might peel off too easily due to the curvature of the bottle, making a standard shape with rounded corners the more durable and professional option.

Key Design Considerations for Die Cutting

Designing for die cutting is different than designing for a screen. As printers, one of the most common issues we face is artwork that is too intricate for the cutting blades to handle cleanly. If your design has extremely sharp acute angles or jagged edges, the physical blade may tear the vinyl or cause the edges to lift prematurely once applied.

We always recommend smoothing out the cut line. You don’t have to change your logo, but the cut path the digital line that tells our machine where to cut should be slightly simplified. Adding a small white (or colored) border around your design is a great way to solve this. It acts as a buffer, ensuring that even if the blade shifts a fraction of a millimeter, you aren’t cutting off text or essential parts of the image.

Another critical factor is bleed. If you want your design to go all the way to the edge without a border, you must extend the artwork past the cut line. Without bleed, any slight shift during production results in a thin white hairline on one side of the sticker, which looks unprofessional. We work closely with our clients to ensure these technical details are sorted before the presses start running.

Durability and Material Choices

A sticker is only as good as its lifespan. Since die cut stickers are often used on outdoor gear, cars, or items that get handled frequently, material choice is non-negotiable. We almost exclusively recommend vinyl over paper for these applications. Vinyl provides water resistance, UV protection against fading, and the flexibility needed to adhere to slightly curved surfaces.

Lamination adds another layer of protection. Whether you choose a matte finish for a modern, sophisticated look or a gloss finish for vibrant, popping colors, that laminate layer is what protects the ink from scratching off in a pocket or fading under the summer sun. When you are focused on increasing brand visibility, longevity is key; a faded, peeling sticker sends the wrong message about the quality of your business.

FAQs

Are die cut stickers hard to peel?

This is a valid concern. Because the backing is cut flush with the sticker, there is no edge to grab. However, high-quality die cut stickers usually come with a crack-and-peel backing or a subtle slit on the back paper. This allows you to bend the sticker slightly to pop the backing open, making application smooth and frustration-free.

What is the difference between a contour cut and a die cut?

In the industry, these terms are often used interchangeably, but technically, a contour cut usually refers to cutting the shape of the design while leaving it on a sheet or roll (often kiss cut). A true die cut is fully separated as an individual unit. If you want a pile of individual stickers to hand out at a trade show, you want die cut.

Can I put die cut stickers on my car?

Absolutely, provided they are printed on the right material. We use weatherproof vinyl and UV-resistant inks specifically for this purpose. Unlike paper stickers which disintegrate in rain, a proper vinyl die cut sticker can last years on a vehicle bumper or window without peeling or losing its color vibrancy.

Conclusion

Choosing the right sticker format might seem like a small detail in the grand scheme of running a business, but it is often the small details that build the biggest trust. Die cut stickers offer a level of polish and personality that standard shapes simply cannot match. They show that you are willing to go the extra mile to present your brand in the best possible light.

Whether you are looking to create a collectible item for your loyal customers or simply want your logo to look its best on a laptop lid, the investment in custom shaping pays off in higher engagement and better brand recall. It transforms a simple piece of vinyl into a connection point.

If you are ready to turn your logo into a high-quality die cut sticker, or if you just need advice on which shape serves your project best, Laguna Digital is here to help. We combine industry expertise with a genuine passion for seeing your business grow, ensuring every print creates a lasting impression.